Which machine manufacture’s turning centre will Kitagawa standard taper (0 taper) back plate fit to?

Kitagawa standard taper (0 taper) backplates can fit to the lathes of manufacturers in the table below.

If you need back plates for machine manufacturers not on the table, please contact your local dealer.

I want to put grease in the chuck, which grease gun should I use?

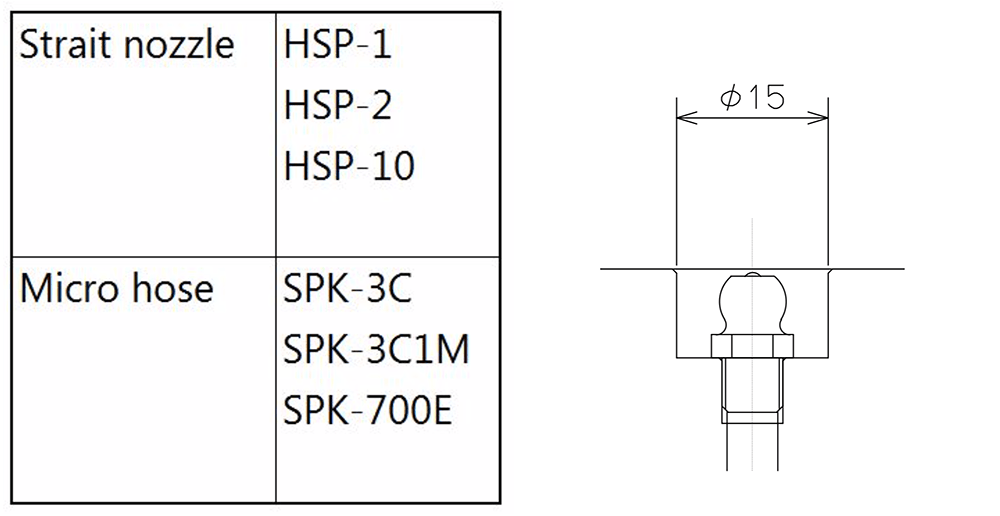

The grease nipple of the BR chuck conforms to JIS B 1575: 2000 type 1 (parallel screw vertical type), and the counterbore diameter is φ15, so purchase a grease gun nozzle compatible with it.

The following table is compatible with Grease Gun nozzles of Yamada Corporation. Please see Yamada Corporation's website for details.

https://www.yamadacorp.co.jp/global/products/grease-gun/

I would like to know a good way to manage the gripping force of the chuck.

KITAGAWA recommends managing the actual gripping force using a static gripping force meter (JFT-S100A).

Even for chucks of the same specifications, the gripping force varies widely depending on various factors such as the greasing condition, the jaw shape, and the viscosity of hydraulic oil. Managing the gripping force is important because an unexpected drop in the gripping force causes the danger such as work scattering.

Oil is leaking out of the rotary hydraulic cylinder. Is it possible to repair it by myself?

Because special test equipment is required for repair completion inspection, rotary hydraulic cylinder repair is done at dedicated factories only. Please contact your nearest dealer.

We also sell seal kits for cylinders according to customers’ requests. However, please understand that it will not be subject to our warranty if a customer replaces seals by himself. Please check the cylinder type and manufacturing number and contact your nearest dealer.

The rotary hydraulic cylinder is the most important device of the workholding system. Mistakes in reassembly may result in the workpiece scattering out during rotation, therefore, a fully trained and qualified engineer who has sufficient mechanical knowledge and understands the above content should repair.

I am using KITAGAWA CHUCK GREASE PRO. Please tell me the most suitable storage method.

Please store KITAGAWA CHUCK GREASE PRO as follows.

·Please store unopened grease in a cool and dark place.

·When storing half-used grease, keep the grease surface flat and completely cover and seal and store it in a cool and dark place.

·The shelf life of grease will be approximately three years after manufacturing if it is stored correctly.

However, grease will deteriorate even during storage and lose its lubricating function, so please use it as early as possible.

Degraded grease becomes darker colour and develops waste acid smell and a large amount of oil on the surface compared to new one. Please take this as sign.

Is there the Safety Data Sheet of KITAGAWA CHUCK GREASE PRO available?

Please download here below.

Safety Data Sheet in English (PDF)